How to Reduce The Damage of Nail Making Machine Tools

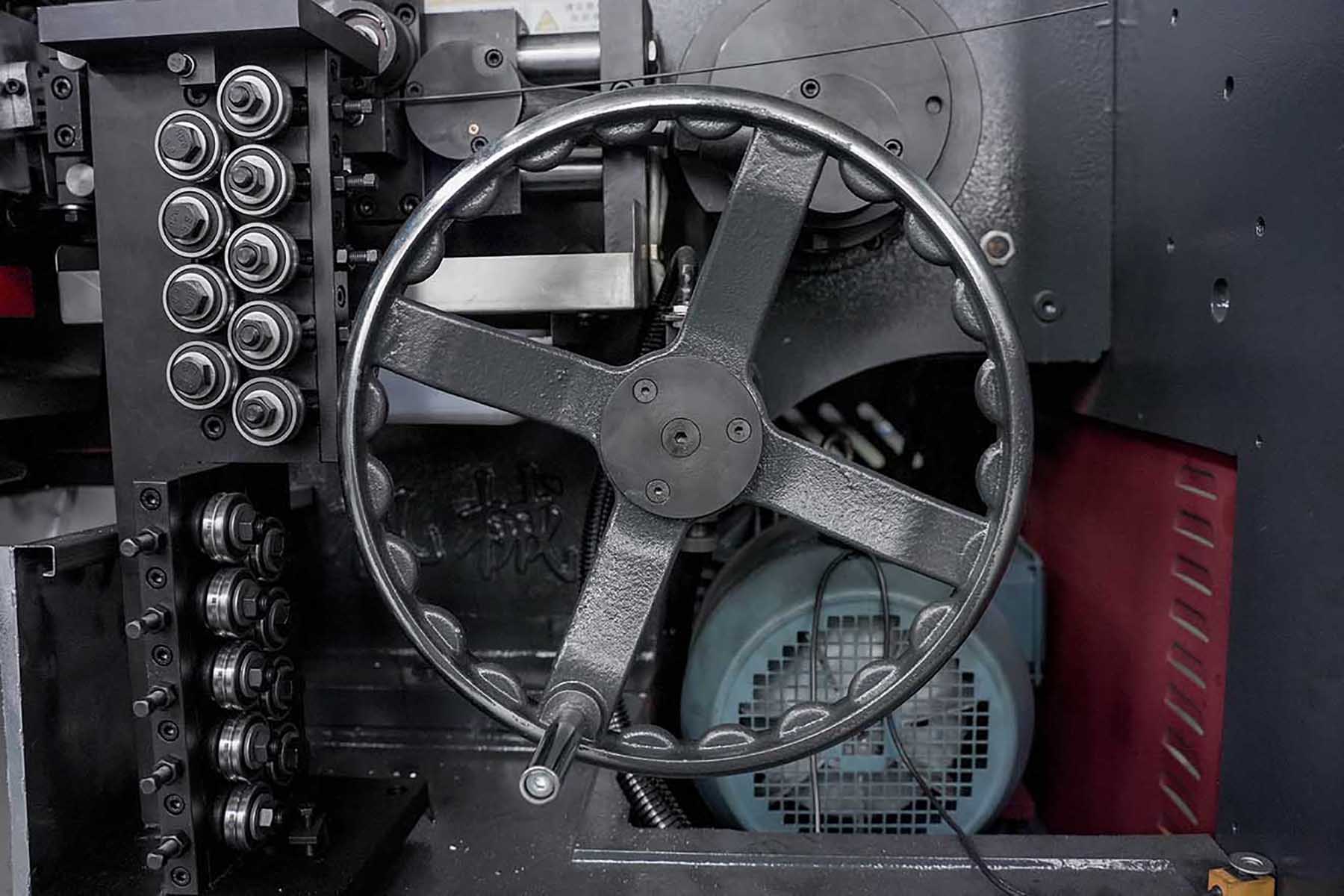

Jun 08, 2023The loss of nail making machine tools often increases production costs and efficiency,this problem will confuse many customers, because in the case of nail making machines, tool damage is likely to occur during work. Sometimes the tool needs to be changed again after only a short time of application. What are the ways to reduce the damage of the nail machine tool?

The first reason may be that the tool is very easily damaged due to the raw material applied. For example, if the raw material we use is relatively hard, then of course, the tool of the nail machine will be seriously damaged; or the raw material has some defects such as dust inclusion and shelter seam, etc. The problem of serious tool damage. Then, if we want to prevent this problem, we must select appropriate raw materials for production and processing, or replace the relative tool for production and processing.

The second reason may be the tool itself. This is because, in the case of manufacturing, the production and processing conditions of different knives are different. We should choose appropriate knives according to the specific situation. Application regulations should vary.

The third reason may be that the equipment is not adjusted properly. In the whole process of manufacturing, if the adjustment is not good, the damage to the nail making machine tool cannot be ignored. Not everything is normal, if there is a problem of being too tight or too loose, it should be adjusted immediately.