In recent years, many nailmaking factories have begun to use ultra-high speed nailmaking machines to replace traditional nailmaking machines.

The capacity of one high-speed nail making machine is equivalent to the capacity of 8-10 ordinary nail making machines. The nails produced by the high-speed nail-making machine adopt the method of mold molding once, so that the quality of the nails is very good, and its shape is more neat and beautiful.

Overview

Product Description

Super High Speed Nail Making Machine is our new design type, it is different from traditional nail making machine, it greatly improve productivity and its max speed can reach 1650pcs/min. With the development of technology, the super high speed nail making machine is more mature, easy operation,and labor saving,which reducing production costs and increasing production efficiency.

Advantages of performance and structure

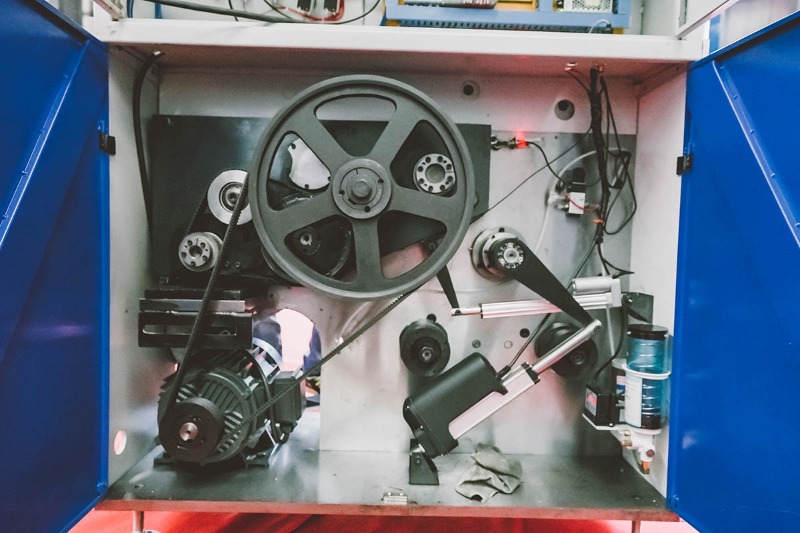

1. The main features of this machine are simple structure, good rigidity, convenient use and low maintenance cost. The straight-shaft cam and the crankshaft are linked with synchronous belts, so the machine is easy to adjust and low in maintenance cost

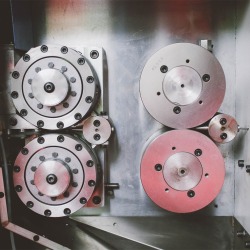

2. The cutters and gripping dies are designed according to the cam lever principle, which is simple and reliable with stable accuracy control.

3. The double punch structure is used for gripping dies to ensure the concentricity of the nail head and the bigger diameter ratio of the nail shank and nail head.

Technical Paramenters

| Moder number | SSS-GDJ-2 | SSS-GDJ-3 | SSS-GDJ-4 |

| Nail diameter | 2.0-2.5mm | 2.1-3.4mm | 2.8-4.1mm |

| Nail length | 32-45mm | 50-75mm | 60-100mm |

| Speed | 1800-2000pcs/min | 1500-1700pcs/min | 1000-1250pcs/min |

| Rated power | 5.5kW+2.2kW | 5.5kW+2.2kW | 7.5kW+2.2kW |

| Dimensions | 1400*800*1580mm | 1400*800*1680mm | 1400*950*1680mm |

| Machine weight | 1500kg | 1800kg | 2000kg |

Machine Features

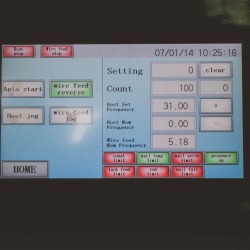

1. Easy operation,change and adjust the cutters, gripping dies and feeding unit while changing nail shank diameter and length.

2. Simplified maintenance, automatic inside oiling system, no grease needed.

3. Very round nail head, two times punching to ensure very good nail heads.

4. Consistent nail shank length, good for making coil nails and strip nails.

5. 24 hours keep working without stop

6. Safe and less noise

7. Durable and cheaper tools, lower using cost.

8. Decrease your production cost.

Detail Images

Packaging and shipping

1. Shipping port: Shanghai

2. Validity: within 30 days

3. Payment terms: 30% T/T down payment in advance and 70% before shipment

4. Warranty: 1 year from date of installation

5. Installation/Operation/Service/Maintenance Manual: Provided In English

6. In wooden pallet, In plastic film, the spare parts and cabinet packed by wooden box.

Our service

1. All required documents (including Installation/Operation/Service/Maintenance Manual) will be provided in English.

2. Engineer will give free training and guide to labors at customer's site if requested.

3. Commissioning charge is $150/day/engineer,and customer will be asked to provide room, meals, round-trip transportation for engineer.

4. We will offer life-long technical guide and maintenance.

5. Warranty:1year from date of installation.

Tags :